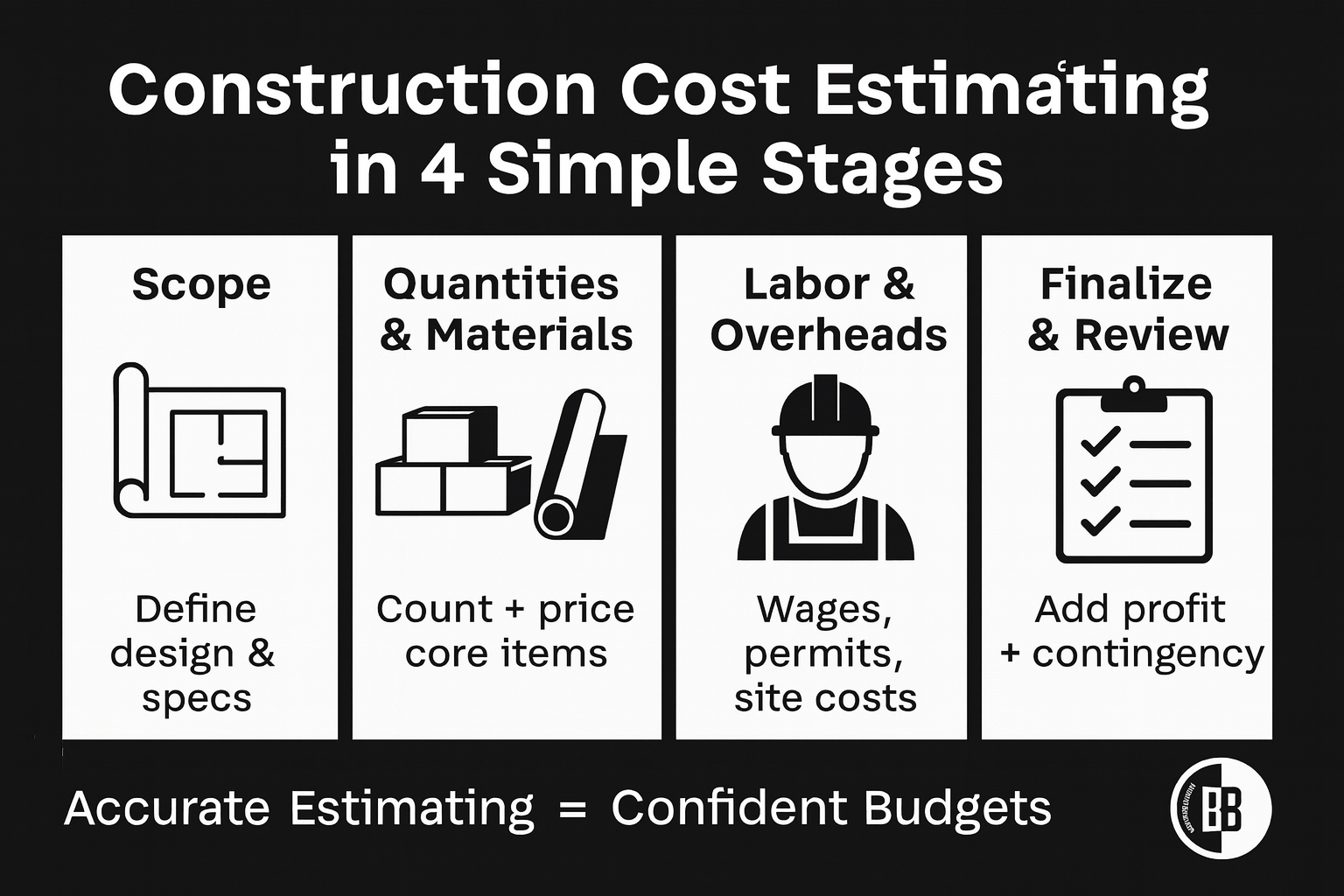

Construction Cost Estimating can feel overwhelming, but breaking it into a clear step-by-step guide makes it manageable. A solid construction cost estimate helps you plan your budget, reduce risks, and make confident decisions. It’s the foundation of any reliable project plan.

With the right process, you can create accurate estimates that reflect materials, labor, and overhead without guesswork. This guide will walk you through each step — from defining your scope to packaging a final estimate — so you can take control of your numbers before the work begins.

Before you can prepare a reliable construction cost estimate, you need to lock down the project scope. This means being clear about the design, specifications, and site conditions. A well-defined scope reduces risks, improves feasibility, and helps you avoid big surprises later in your construction project.

To create a clear scope for the construction estimate, gather every document that explains your design and site requirements. These items act as the foundation for accurate pricing.

Many estimates fail because the scope isn’t complete. Missing or vague details often inflate costs later.

The next step in your construction estimate is to measure and count everything. A quantity takeoff helps you calculate the square footage of floors, walls, and ceilings, along with the materials and systems required. This creates a reliable baseline for material costs and avoids surprises later in the project.

For accuracy, start with the building’s skeleton. Measure structural items like concrete, steel, and masonry. These big-ticket components form a large part of your budget and must be calculated carefully.

Next, move inside to capture details that directly affect both comfort and cost. Include finishes and building systems in your construction quantity takeoff to create a complete picture.

Once your quantities are ready, it’s time to look at material costs. Get updated supplier quotes, check market rates, and consider waste factors. Accurate material pricing construction ensures your house construction cost forecast reflects reality instead of guesswork, keeping your construction costs within budget.

Start with the backbone items. These make up most of the budget, and small changes here can shift totals quickly.

Next, price visible items that affect comfort and style. These vary by brand and finish, so capture a full range.

After pricing materials, you need to account for labor costs and equipment costs. A good estimate looks at crew hours multiplied by wage rates and adds rental charges. Considering productivity, supervision, and idle time ensures your labor cost estimate reflects real conditions on a construction project.

Skilled labor makes up a major share of direct costs. Break tasks into hours and apply the right wage. Don’t forget supervision or overtime when the schedule is tight.

Machines speed up work but add expenses. Factor in rental fees, fuel, and downtime. An accurate equipment rental cost forecast helps prevent budget overruns.

Beyond materials and labor, every construction project carries hidden expenses. These indirect costs and overhead costs include permits, site offices, and company expenses that keep the project running. Capturing them accurately is a key part of construction cost estimating and prevents gaps in your final budget.

Costs tied to the site itself are often overlooked. These are ongoing needs that keep the project safe and compliant.

Your builder’s back office also adds costs. These aren’t visible on-site but still support the work. Ignoring them leads to underpricing.

No construction cost estimate is complete without planning for the unexpected. Market shifts, design changes, and delays can raise expenses. Adding a proper contingency in the construction estimate and covering the right construction insurance cost protects you from surprises and ensures more accurate estimates.

A contingency is a buffer for unexpected expenses. The percentage depends on project stage — early designs may need 10–15%, while detailed plans can use 5%. This cushion helps you manage risks without scrambling for funds later.

Insurance covers risks no budget can fully control. Premiums vary, but the cost is far less than a major loss.

After adding direct and indirect costs, the final step is to include a fair profit margin in construction. This ensures the contractor is compensated and the project stays viable. A healthy margin balances business needs with client budgets while keeping the total cost transparent.

Many confuse markup with margin. Markup is the percentage added to costs, while margin is the actual profit earned after expenses. For example, a 10% margin usually needs around a 12% markup. Clear math helps both the general contractor and client avoid confusion.

Owners should also view profit in terms of return on investment. Paying a fair profit supports quality work, reduces risk, and helps ensure timely delivery. Contractors who cut profit too thin may compromise performance, which can cost more in the long run.

Once your numbers are ready, organize them into a clear construction bid package. A structured presentation with inclusions, exclusions, and alternates makes it easy for owners and specialty contractors to understand. This step ensures the construction cost estimate is both transparent and accurate.

Clarity avoids disputes later. Spell out exactly what’s included and what is not.

Before sending out the package, ask another construction estimator to review. A fresh set of eyes catches errors and validates pricing. An estimate review checklist helps confirm all costs, so you deliver a reliable package with confidence.

Not every project needs the same level of detail. The right method depends on the stage of your construction project. Early estimates focus on speed and feasibility, while later ones demand precision. Choosing wisely ensures an accurate construction cost without wasting time or resources.

This is the fastest method. It uses historical data from similar jobs to give a ballpark number. Ideal for early planning, but accuracy is limited.

Here, costs are tied to measurable drivers like the number of rooms, stories, or units. It’s more refined than analogous and supported by construction estimating software.

This is the most detailed method. Every material, labor task, and system is priced line by line. It creates a precise construction cost estimation, but it takes time and effort.

This method factors in uncertainty by creating a range. It gives you best-case, worst-case, and most-likely numbers, then blends them into a more realistic forecast.

| Method | When to Use | Strengths | Weaknesses |

| Analogous (Cost per Sq Ft) | Early planning, feasibility | Fast, simple | Low accuracy |

| Parametric | Schematic design | Uses real drivers | Needs reliable data |

| Bottom-Up | Detailed design | High accuracy | Time-consuming |

| Three-Point | Risk-heavy projects | Captures uncertainty | Needs judgment |

Even a detailed construction cost estimate can go wrong if common errors are overlooked. These mistakes inflate budgets, reduce reliability, and create unexpected expenses. Avoiding them ensures a more accurate estimate for your project.

How accurate are construction estimates?

Accuracy depends on detail. Early-stage numbers may vary 15–20%, while detailed line-item estimates can be within 5%. Adding contingency improves reliability.

What affects construction cost the most?

The biggest factors are material costs, labor rates, site conditions, and design choices. Each of these has a direct impact on the building construction cost.

How long does it take to prepare an estimate?

A basic construction cost estimate can be done in a few days. A full bid with vendor quotes may take several weeks, depending on project complexity.

Do construction costs change by location?

Yes, construction costs do change by location. Local wages, material availability, and transport costs affect pricing. Adjusting for your region is critical for a realistic cost estimation.

Why is contingency important in an estimate?

Contingency covers unexpected expenses like design changes or delays. Without it, even small risks can cause big budget overruns in a construction project.

Getting an accurate construction cost is about more than numbers — it’s about building trust in your plan. By following each step carefully, you reduce risks, control your budget, and set your construction project up for success. A professional touch ensures your total cost is reliable and complete.

Next Step: Share your drawings today and get a clear, line-by-line professional construction cost estimate tailored to your project.