If you're planning a building project in 2025—whether it's a new home, a renovation, or a commercial site—you'll need to estimate how much it's going to cost. That’s called construction estimating, and there are two main ways to do it: the old-school manual method or the newer digital approach using software.

In this blog, we’ll break down both methods in simple terms. You’ll see how they work, what they cost, where they save you time, and which one might suit your needs best. Whether you're a contractor, a homeowner, or someone managing a build, this guide will help you make a smarter choice.

Construction estimating is the process of forecasting the total cost of a construction project before work begins. It involves calculating material quantities, labor hours, equipment needs, and other expenses to create a clear and accurate financial plan. This estimate forms the foundation for budgeting, bidding, and overall project management.

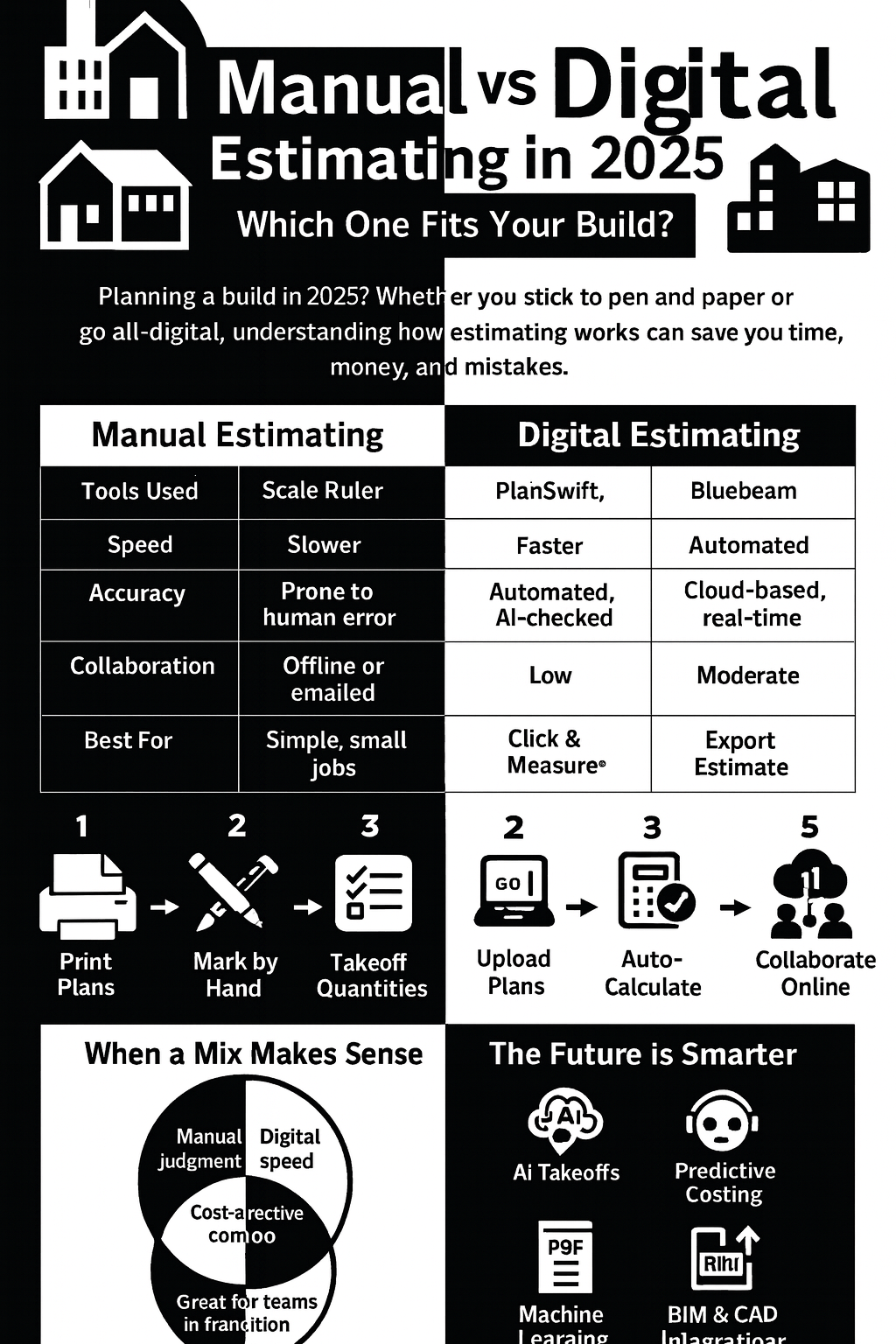

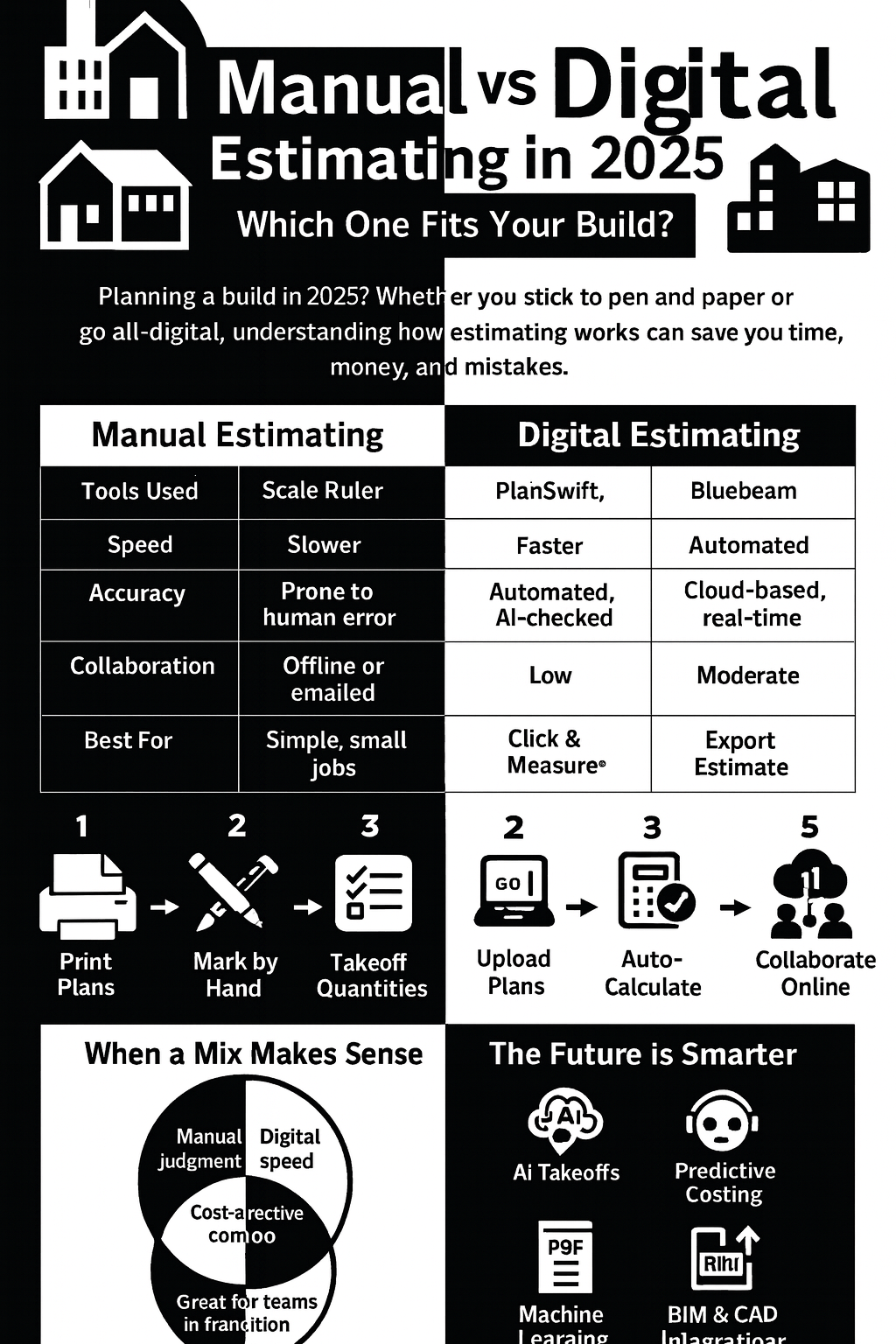

In 2025, professionals are facing a growing divide: stick with traditional manual estimating methods or shift to digital tools. Both paths serve the same goal—accurate cost projections—but take very different approaches. As estimating trends evolve, the pressure to improve speed, reduce human error, and stay competitive is stronger than ever.

That’s why understanding how construction estimating works, and what’s changing in the industry, is critical. The debate between manual and digital is no longer just about convenience—it’s about performance, risk, and long-term project success.

Manual estimating is the traditional way builders calculate project costs—using printed plans, scale rulers, highlighters, and tools like Excel. It’s hands-on and often time-consuming, but still widely used. Many professionals trust it for its familiarity, even if it leaves room for human error and slows things down on complex jobs.

Manual estimating follows a straightforward, pen-and-paper approach. Estimators work directly off printed plans, jot down quantities by hand, and use spreadsheets like Excel to calculate totals. It’s a familiar process for many, but it can be slow and prone to human error—especially when things get busy or complex.

Everything starts with paper. Estimators print the construction drawings, spread them out, and begin marking up key areas. Highlighters, pens, and sticky notes often come into play here.

Using a scale ruler or visual reference, quantities are measured and written down line by line. This is the heart of manual estimating—no software, just judgment and attention to detail.

Once quantities are noted, they’re entered into Excel or another spreadsheet program. This is where costs are applied to each item and totals start to take shape.

With no automation to catch mistakes, every formula and number must be reviewed. A second look helps avoid costly issues later on.

After everything is double-checked, the completed spreadsheet becomes the official estimate. It’s polished, formatted, and sent along with the bid.

Manual estimating works best for small projects or repeat jobs. But on larger builds, it’s slower, harder to scale, and increases the risk of missing something important.

Digital estimating is a modern approach to construction cost planning that uses software instead of pen and paper. With tools like PlanSwift, Bluebeam, or cloud-based platforms, estimators can quickly measure plans, generate takeoffs, and calculate costs. It speeds up the process, reduces errors, and fits the fast-paced demands of 2025.

Digital estimating follows a streamlined, software-driven workflow that replaces slow, manual steps with speed, accuracy, and automation. In 2025, it’s not just about faster takeoffs—it’s about smarter collaboration and fewer mistakes in estimating whether it is residential or commercial estimating. From uploading blueprints to generating live reports, here’s how a typical digital estimating process actually works.

Start by importing your project’s digital blueprints (usually in PDF or DWG format) into cloud-based estimating software. This becomes your working file for all takeoffs and calculations.

With built-in digital takeoff tools, you simply click and drag to measure areas, lengths, and counts. No scale rulers—just fast, accurate measurements on-screen.

The software applies formulas and item libraries to generate cost estimates instantly. Tools often include smart features powered by artificial intelligence that suggest quantities or flag inconsistencies.

Team members can review, comment, and make adjustments within the platform. Cloud-based collaboration ensures everyone is working from the same, most updated version.

Final reports can be exported in multiple formats—spreadsheets, PDFs, or client-ready summaries—making it easy to share clear, organized cost data with stakeholders.

When comparing digital vs manual construction estimating in 2025, it’s not just about how they work—it’s about how much they cost you in time, money, and effort. From software fees to labor hours, here’s a breakdown of where each method shines, and where hidden costs might catch you off guard.

Manual estimating has little to no upfront investment—just paper, Excel, and a scale ruler. Digital tools often require licensing fees, subscriptions, or setup costs.

Manual quantity takeoff takes longer. Estimators spend more time measuring, checking, and recalculating. Digital quantity takeoff automates much of that, saving hours on every project.

Over time, digital estimating improves cost management through forecasting, audit trails, and scalable workflows. Manual systems rarely offer that kind of repeatable value.

Digital tools require updates, backups, and occasional training. Manual methods don’t—but they lack automation, and errors can be expensive to fix down the line.

Automation helps teams estimate more projects in less time, with fewer mistakes. That often leads to better margins and more accurate forecasting—advantages manual workflows can’t match.

Manual and digital estimating offer two very different experiences—and in 2025, those differences matter more than ever. Whether you’re focused on cost control, collaboration, or cutting down on human error, this side-by-side table shows how both methods stack up in real-world construction workflows.

|

Feature |

Manual Estimating |

Digital Estimating |

|

Cost |

Low upfront cost, high long-term labor |

Higher software cost, better long-term efficiency |

|

Time |

Slower process, especially for complex jobs |

Automated steps save significant hours |

|

Accuracy |

Prone to human error and miscalculations |

More precise with built-in checks and formulas |

|

Collaboration |

Limited to physical or emailed files |

Cloud-based with real-time version control |

|

Skill Level |

Relies on experience and manual methods |

Requires software familiarity, but easier to scale |

Digital estimating isn’t just a trend—it’s the 2025 standard. With tools like PlanSwift, Bluebeam, and CostX, estimators are ditching paper and switching to automated, cloud-based workflows. These platforms save time, reduce costly errors, and keep teams in sync. It’s smart, scalable, and built for modern construction demands.

Digital estimating software automates takeoffs, cost calculations, and reporting—cutting down hours of manual work into minutes.

With cloud access, team members can collaborate in real time, share updates, and work on the same commercial or residential estimates—even from different locations.

Software like PlanSwift, Bluebeam, and CostX combines drawing analysis, material lists, and pricing tools into one streamlined platform.

Many estimating platforms now use artificial intelligence to suggest quantities, flag inconsistencies, or highlight areas that need review.

Whether you’re estimating a kitchen remodel or a multi-million dollar build, digital estimation tools adjust to fit your workflow and project size.

In 2025, digital tools aren’t optional—they’re essential for staying competitive, reducing risk, and delivering faster, more reliable estimates.

Sometimes, going fully digital isn’t practical—and that’s where hybrid estimating fits in. By blending manual insight with digital tools, teams can work around limitations like experience gaps, software costs, or project complexity. It’s not about choosing sides—it’s about using what works best together for smarter project management.

As construction estimating evolves in 2025 and beyond, AI and automation are driving major changes. From smarter suggestions to predictive estimates, the tools are learning how to think ahead. Estimators will still guide the process—but with machine learning, the future is faster, more accurate, and way less stressful.

1. What’s the real difference between manual and digital estimating?

The real difference between manual and digital estimating is that manual estimating uses paper plans, rulers, and spreadsheets—everything is done by hand. Digital estimating uses software that speeds things up, cuts down on errors, and makes collaboration easier.

2. Is manual estimating still a good option today?

Yes, manual estimating still a good option today, especially for small or one-off projects. If you’re comfortable with it and the job isn’t too complex, manual estimating still works. But it’s not ideal for larger or fast-paced builds.

3. Why are more people switching to digital estimating?

More people switching to digital estimating because it’s faster, more accurate, and built for how modern construction works. You can measure plans on-screen, automate cost calculations, and share updates instantly with your team.

4. Does digital estimating software cost a lot?

Yes, digital estimating software cost a lot. Some tools have upfront costs or monthly fees, but many users save money in the long run by cutting down on hours worked and reducing mistakes.

5. Can I use both manual and digital methods together?

Yes, you can use both manual and digital methods together. You might do manual takeoffs and plug numbers into a digital tool, or use digital plans but rely on your experience for final adjustments.

Choosing between manual and digital construction estimating in 2025 really depends on your team, your tools, and your project needs. Manual estimating still works for small or familiar jobs—but it can be slow and more prone to mistakes. Digital estimating, on the other hand, offers speed, accuracy, and real-time collaboration that modern builders and managers rely on more and more.

If you’re just starting out, a hybrid approach—using both methods—can help bridge the gap while your team gets comfortable with digital tools. But looking ahead, automation and AI-driven platforms are clearly shaping the future of cost estimation.

No matter your method, the goal stays the same: clear numbers, smart planning, and better project control. Use what works for you now—but don’t ignore where the industry is headed.