In the construction industry, speed and accuracy in the estimation process often make the difference between winning and losing a project. Every delay in construction increases estimating risks, missed deadlines, lost bids, and shrinking profitability. With competition rising and margins tightening, efficiency has become the defining measure of success.

Research backs this urgency: according to McKinsey, poor productivity and delays in pre-construction workflows cost the industry billions each year. The answer lies in digital tools that transform how estimates are created. By adopting digital takeoff software, contractors can improve productivity, streamline project management, and secure the competitive advantage needed to thrive in today’s market.

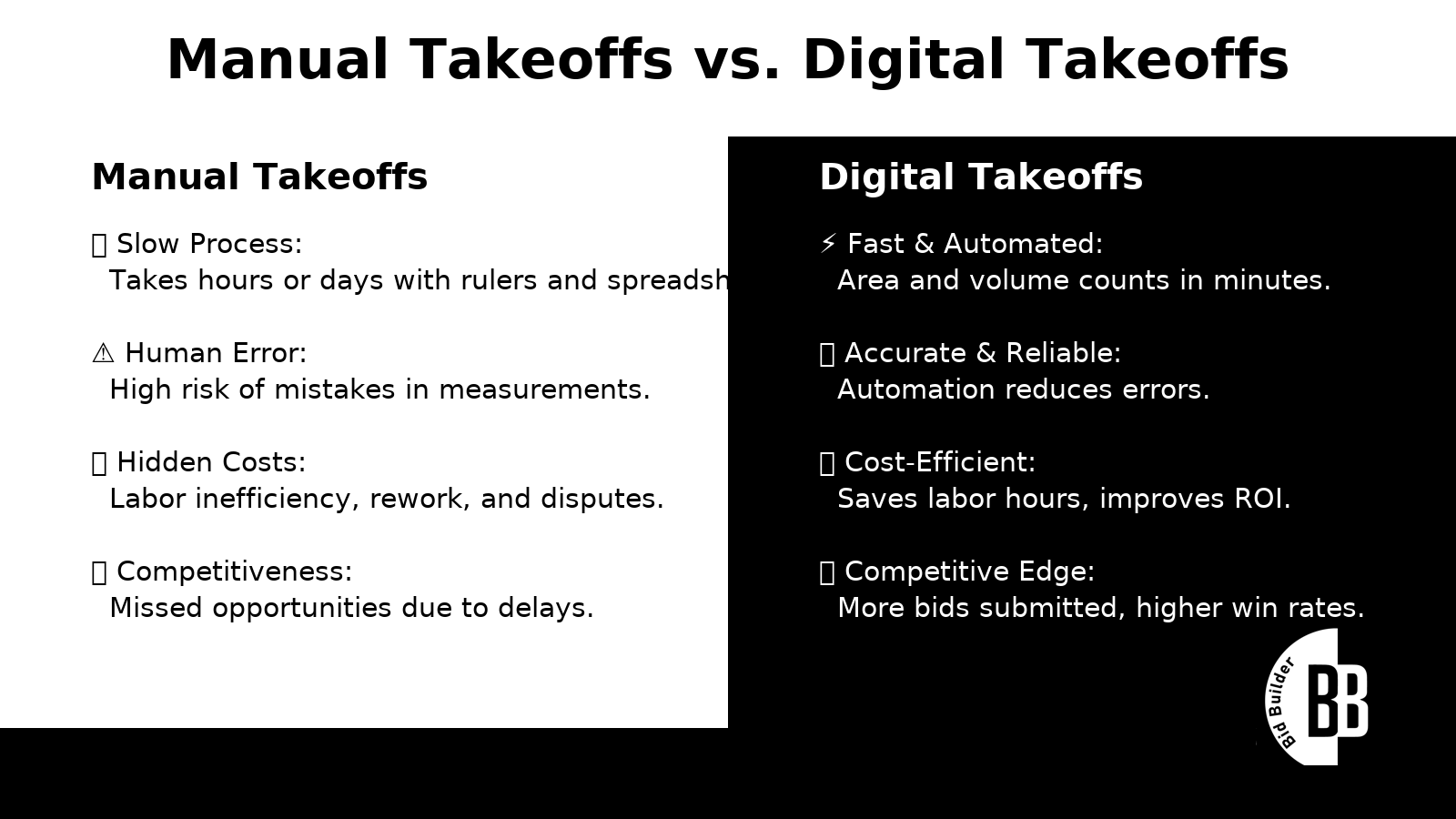

In construction estimating, time and accuracy are the lifeblood of successful bidding. Yet many companies still rely on manual takeoffs—a process tied to spreadsheets, pens, and rulers. While once standard, these methods have become a bottleneck in today’s fast-paced market, slowing down the estimation process and eroding competitiveness.

Let’s look at why manual methods hold your team back.

Manual takeoffs demand hours of line-by-line measurement, cross-checking, and data entry into spreadsheets. This pace not only delays job costing but also forces contractors to miss out on competitive bidding windows. In industries where speed defines success, slow estimating means lost opportunities and a growing risk of falling behind more agile competitors.

Every manual entry is vulnerable to human error—fat-finger mistakes, missed quantities, or overlooked line items. These small missteps compound into larger estimating problems, leading to underbids, overbids, or costly rework on the project site. Studies in the construction industry have shown that manual quantity takeoff can increase uncertainties, undermining reliability at every stage of the project.

Errors aren’t just mistakes—they’re liabilities. Each one damages trust, creates disputes, and adds unnecessary financial strain. Digital methods, by contrast, significantly reduce risk through automated precision and built-in validation.

Beyond speed and accuracy, manual methods carry a hidden cost. Labor hours pile up as estimators spend days recalculating figures, updating spreadsheets, and double-checking work. This inefficiency inflates overhead costs, particularly as inflation pushes labor expenses higher. For construction projects operating on tight margins, these hidden costs cut directly into profitability.

Accounting systems reveal the truth: inefficiency eats into revenue. Companies sticking with manual methods often see slower growth and diminished competitiveness, while those embracing digital takeoff solutions free up resources for innovation and project expansion.

Digital takeoffs are transforming how construction professionals approach residential or commercial estimating. Instead of spending hours on manual calculations, estimators now use digital tools that turn blueprints into data-driven insights. By leveraging digital takeoff software, contractors save time, reduce errors, and generate faster, more reliable estimates for every project.

At its core, a digital takeoff replaces the ruler and spreadsheet with automation, precision, and collaboration. Let’s break it down.

A digital takeoff is the process of extracting quantities and measurements directly from PDF plans or CAD drawings. With the help of digital takeoff software, estimators can automate quantity calculations, markups, and reporting. This means less time measuring and more time analyzing. The result? Faster, more consistent data that strengthens every bid.

The strength of digital takeoffs lies in their features. Modern platforms allow estimators to import PDF plans, apply CAD overlays, and collaborate in real time through cloud-based systems. These features eliminate redundant work and allow teams to share updates instantly. By streamlining the takeoff process, digital solutions cut hours—sometimes days—off traditional estimating workflows.

Collaboration is no longer limited to a single workstation. With cloud access, project managers, estimators, and contractors can review and refine estimates together, ensuring smoother project starts.

Beyond PDFs and CAD, the next frontier of digital takeoffs is Building Information Modeling (BIM). With BIM workflows, estimators can integrate automated precision, live updates, and even forecasting into their workflow. This creates a comprehensive construction management system where every estimate connects directly to project execution.

Tools like PlanSwift, Bluebeam Revu, and Autodesk demonstrate how automation isn’t just speeding up takeoffs—it’s making estimates smarter and more reliable. By linking design with data, BIM ensures construction professionals can construct estimates with confidence while staying ahead of project risks.

Digital takeoffs don’t just replace manual methods—they revolutionize them. By cutting hours of repetitive work, reducing costly mistakes, and allowing teams to collaborate in real time, these tools fundamentally change how contractors construct estimates. The result is faster bids, smoother workflows, and more successful projects.

Let’s explore the four ways digital takeoffs create speed and efficiency.

Manual spreadsheets often force estimators to calculate areas, volumes, and counts one line at a time. Digital tools eliminate that burden through automation, instantly pulling measurements from plans. This not only saves hours but also ensures that every quantity takeoff is consistent and reliable. With automation, your team can focus on strategy, not endless data entry.

Accuracy is more than just a confidence booster—it speeds up approvals. With fewer errors in the estimating process, digital takeoffs provide true bid data that clients and stakeholders can trust. This reduces back-and-forth revisions and keeps projects moving. The impact is clear: less wasted time, stronger construction estimates, and more awarded contracts.

When estimates are reliable, trust grows. And when trust grows, approvals happen faster—giving contractors a decisive edge.

Modern construction projects demand seamless teamwork. Cloud-based digital takeoff platforms allow estimators, project managers, and general contractors to access and update the same file in real time. No more version confusion, delayed handoffs, or siloed data. Instead, team members can collaborate instantly, speeding up both the bidding process and overall project preparation.

Collaboration is no longer limited by location—digital takeoffs create a shared workspace that accelerates every step of commercial or residential estimating.

The power of digital takeoffs isn’t just theory—it’s proven. For example, construction firms in New York City and within the Australian construction industry have reported cutting their estimating time by nearly 50% after adopting platforms like PlanSwift or Bluebeam. These real-world results show how companies gain a competitive edge while boosting overall productivity.

Case studies confirm what many already know: digital takeoffs create faster, smarter, and more successful projects.

| Factor | Manual Takeoffs | Digital Takeoffs |

| Speed | Hours to days using rulers and spreadsheets | Minutes with automation and built-in calculations |

| Accuracy | High risk of human error and miscounts | Greater reliability with automated precision |

| Productivity | Limits estimators to a few bids at a time | Enables more bids, boosting team productivity |

| Collaboration | Siloed data, hard to share | Cloud-based access for team members and contractors |

| Cost Impact | Hidden costs from rework and inefficiency | Stronger ROI through faster, more accurate estimates |

| Competitiveness | Missed opportunities due to slow turnaround | More competitive bids and higher win rates |

While faster estimates are a clear win, the real value of digital takeoffs runs deeper. These tools don’t just save time—they reduce risk, improve team productivity, strengthen your bids, and integrate seamlessly with broader management systems. Together, these benefits give construction companies a lasting competitive edge.

Every contractor knows the pain of costly change orders and disputes caused by inaccurate estimates. Digital takeoffs minimize human error by automating calculations and embedding risk analysis into the workflow. This ensures greater reliability, fewer surprises during construction, and more successful projects delivered on budget and on time.

By improving accuracy upfront, companies safeguard their reputation and reduce downstream financial risks.

With digital takeoffs, team members can generate more construction estimates in less time, freeing capacity to handle additional bids and projects. The automation of repetitive work allows estimators to focus on higher-value tasks like strategy, client communication, and market analysis. The result? Greater productivity and a measurable competitive advantage.

Digital workflows also create stronger collaboration across departments, reducing bottlenecks and making teams more efficient.

Strong bids win projects, and digital takeoffs provide the true bid data that sets winning proposals apart. By improving accuracy and efficiency, contractors can submit more competitive bids without sacrificing quality. Integrated forecasting tools and accounting systems help ensure bids are both aggressive and realistic, boosting win rates in tough markets.

Reliable data gives clients confidence, which translates into faster approvals and more awarded contracts.

Digital takeoffs don’t stand alone—they connect with broader comprehensive construction management systems. By integrating with project management and accounting systems, companies gain streamlined operations, smoother handoffs, and better financial oversight. Platforms like Procore and Sage have already shown how these integrations save both time and money while building trust with clients.

For construction companies, alignment means one unified source of truth—reducing errors, improving forecasting, and driving consistent growth.

Moving from manual methods to digital solutions isn’t just about adopting new software—it’s about reshaping how your team works. The transition requires planning, training, and a vision for the future. When done right, it empowers team members to work smarter and prepares companies for long-term success in the estimating process.

Adopting digital takeoff tools works best with a structured rollout. Companies should start by testing software, training staff, and gradually phasing out manual methods. Incorporating automation and linking platforms to project management systems ensures estimates remain accurate and collaborative. By taking this step-by-step approach, teams avoid disruption while building confidence in their new workflows.

It’s natural for construction professionals to hesitate when asked to replace old habits with new tools. The key to overcoming resistance lies in clear communication. Showing how digital takeoffs improve productivity, reduce risk, and simplify various aspects of estimating helps teams see the value. Demonstrating ROI early—through faster, more accurate bids—creates buy-in and eases adoption.

When people experience the benefits firsthand, skepticism turns into advocacy.

Looking ahead, Building Information Modeling (BIM) is set to redefine estimating. By linking BIM with digital takeoff platforms, companies gain predictive insights, real-time updates, and advanced forecasting capabilities. This integration doesn’t just speed up estimates—it creates smarter, more resilient workflows that support successful projects across the board.

Industry experts already highlight BIM as the foundation of next-generation estimating, and early adopters are gaining the competitive edge. Companies that prepare now will lead the way in the years ahead.

Q1: What is a digital takeoff in construction?

A digital takeoff is the process of using software to measure areas, lengths, and quantities directly from digital blueprints such as PDFs or CAD drawings. Unlike manual takeoffs that rely on rulers and spreadsheets, digital takeoffs use automation to speed up the estimation process and reduce errors.

Q2: How do digital takeoffs save time compared to manual methods?

Digital takeoffs save time by automating repetitive calculations like area and volume counts. Instead of spending hours on spreadsheets, estimators can generate results in minutes. This allows construction professionals to prepare more competitive bids and focus on strategy rather than data entry.

Q3: Are digital takeoff tools accurate?

Yes, digital takeoff software is designed to improve reliability by reducing human error. With features like automated quantity calculations and risk analysis, contractors get more precise estimates. This accuracy helps avoid costly mistakes, ensures better forecasting, and builds trust with clients during the bidding process.

Q4: Can digital takeoffs help my entire team, not just estimators?

Absolutely. Modern digital solutions are cloud-based, meaning team members such as project managers, general contractors, and accounting staff can collaborate in real time. Everyone works from the same data, which improves communication and ensures the entire construction project runs more smoothly.

Q5: What role does BIM play in digital takeoffs?

Building Information Modeling (BIM) takes digital takeoffs further by linking estimates with 3D models and live project data. This allows for better forecasting, fewer uncertainties, and more comprehensive construction management. Experts view BIM as the future standard for accurate and efficient construction estimates.

Q6: Do digital takeoff tools integrate with other construction software?

Yes, most digital takeoff platforms integrate with project management and accounting systems. This means estimates can flow directly into job costing, scheduling, and financial forecasting. The result is a unified system that saves time, reduces errors, and increases overall productivity.

Q7: Is switching from manual methods to digital takeoffs difficult?

Not at all. Many companies start small—testing a digital takeoff tool on one project, training staff, and then expanding use. Once teams see the speed and accuracy improvements, adoption becomes easier. The key is gradual integration and clear communication of the benefits.

In today’s construction industry, speed and accuracy aren’t just advantages—they’re requirements. Manual methods can’t keep up with the pace of modern projects, while digital takeoffs powered by automation deliver faster results, sharper precision, and a clear competitive edge. Companies that embrace this shift position themselves for more bids won and more successful projects delivered.

Industry leaders already agree: digital estimating is no longer optional—it’s essential. With tools that support smarter forecasting and tighter collaboration, construction companies can move beyond outdated methods and into a future defined by efficiency, trust, and growth. The next time you prepare an estimate, let digital takeoffs do the heavy lifting.