Every construction project begins with a number — an estimate meant to guide decisions, secure budgets, and shape expectations. When that number is wrong, even slightly, the ripple effect can drain resources, delay timelines, and cut into profits. Inaccurate estimates don’t just affect the bottom line; they weaken trust and disrupt project forecasting.

Accurate estimating is more than a technical task — it’s the backbone of cost efficiency and business credibility. A well-prepared estimate anchors your project budgeting process, ensures fair comparisons to market value, and helps stakeholders make confident decisions. In today’s competitive construction landscape, avoiding common estimating mistakes is not just smart — it’s essential for sustaining long-term profitability.

Behind every miscalculated estimate lies human judgment — and human error. Estimators often fall into predictable patterns driven by overconfidence, optimism bias, and the pressure to win bids. These subtle influences create what experts call estimation bias, where instinct overtakes data and experience is mistaken for certainty.

To avoid these traps, it’s essential to understand the human factor behind numbers — the emotions, assumptions, and shortcuts that distort decision-making. Recognizing these tendencies helps bring balance, common sense, and accountability back into project forecasting.

Key Psychological Drivers of Estimation Errors

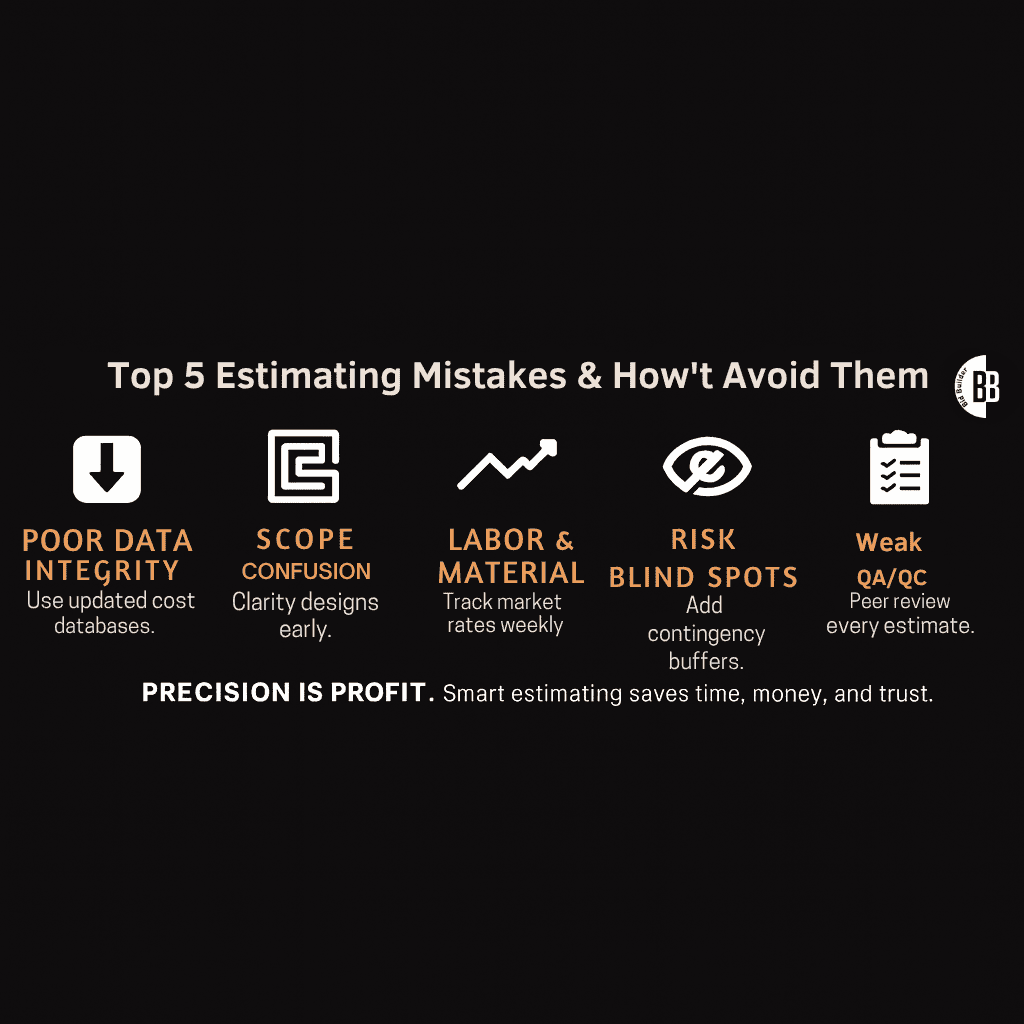

Every inaccurate estimate can usually be traced back to one of five root causes. These aren’t random errors — they stem from weak data, unclear designs, shifting markets, ignored risks, and poor quality control. Understanding these factors helps estimators build stronger systems and deliver more dependable forecasts.

When estimates rely on outdated data or missing information, errors multiply quickly. A weak cost database or unverified digital assets leads to inaccurate estimates that can derail a project before it begins. Regular updates, validation, and version control are essential for reliability.

Misreading plans or overlooking design details causes major cost forecasting issues. Unclear project drawings or evolving solar power systems often lead to design changes that shift budgets midstream. Clear documentation and early coordination between design and estimating teams prevent misalignment.

Fluctuating labor costs and raw material prices are among the biggest threats to accuracy. Factors like market fluctuation, material escalation, and supply chain issues affect every common construction project. Smart estimators track trends and build flexibility into pricing models.

Ignoring uncertainty is one of the costliest mistakes in estimation. Without proper contingency planning, even small disruptions can escalate into budget overruns. Projects with off-grid systems or variable cost basis must include allowances for estimation uncertainty and project risk.

Estimation is not just calculation — it’s validation. A missing QA/QC system, lack of peer review, or skipped cost checks can erode precision over time. Embedding common sense and structured review into workflows ensures cost validation and strengthens accountability across teams.

Avoiding mistakes isn’t about luck — it’s about building structure. A resilient estimating system blends technology, training, and real-time data. It ensures that every forecast is grounded in facts, not assumptions, and that teams have the right tools to maintain accuracy and consistency across all projects.

A clear framework for cost control allows estimators to make confident decisions, reduce waste, and maintain trust in every number.

Step-by-Step Prevention Strategy

Real-world projects offer the best proof that precision pays off. Across industries, teams that applied hybrid estimating — combining top-down forecasting with bottom-up detailing — achieved stronger accuracy and faster ROI recovery. These stories show how data, discipline, and adaptability can turn estimating challenges into measurable wins.

Key Lessons from Successful Projects

1. Why do cost estimating mistakes happen so often in construction?

Cost estimating mistakes usually come from incomplete data, unclear designs, or human judgment errors. Estimators sometimes rely on old benchmarks, rush calculations, or underestimate risks — all of which lead to forecasting errors and budget overruns.

2. What is estimation bias, and how does it affect accuracy?

Estimation bias happens when confidence or optimism outweighs data. Estimators often assume best-case scenarios or underestimate labor and materials. Recognizing this human factor helps improve objectivity and achieve more accurate estimates.

3. How can poor data integrity impact a project’s outcome?

When outdated data or unverified information enters your cost database, even the most skilled estimator can go wrong. It leads to unrealistic bids, profit loss, and scheduling issues that undermine trust and accountability.

4. What’s the best way to prevent common estimating mistakes?

Build internal cost databases, adopt smart estimating software, and train teams to question assumptions. Regular reviews, AI benchmarking, and version tracking all support accurate forecasting and stronger cost control.

5. How does labor and material volatility affect estimates?

Rapid changes in labor costs or material prices can throw estimates off balance. Tracking market fluctuations and allowing for escalation in your estimates ensures that pricing stays realistic throughout the project.

In construction, precision isn’t a luxury — it’s the difference between profit and loss. Every accurate estimate builds trust, strengthens cost management, and safeguards long-term performance. A well-structured project forecasting system ensures that numbers reflect real-world outcomes, not assumptions.

Looking ahead, the future belongs to teams that treat estimation as a discipline — one rooted in data, strategy, and renewable learning. When every calculation is deliberate and informed, project success becomes a consistent result, not a fortunate outcome.